THE INTRALOGISTICS CONNECTIVITY SURVIVAL KIT

That 60-minute line stop? It started with one weak cable.

Download your free guide to finding and fixing the #1 cause of connectivity failure and application downtime.

Spot hidden weak links in under five minutes.

Know the real downtime cost for your line, in €/$/IDR.

Pick the right cable spec first time, every time.

THE INTRALOGISTICS CONNECTIVITY SURVIVAL KIT

That 60-minute line stop? It started with one weak cable.

Download your free guide to finding and fixing the #1 cause of connectivity failure and application downtime.

Spot hidden weak links in under five minutes.

Know the real downtime cost for your line, in €/$/IDR.

Pick the right cable spec first time, every time.

You now have full access to all tools

Instantly use the Downtime Calculator and Connectivity Audit to understand your risks and costs.

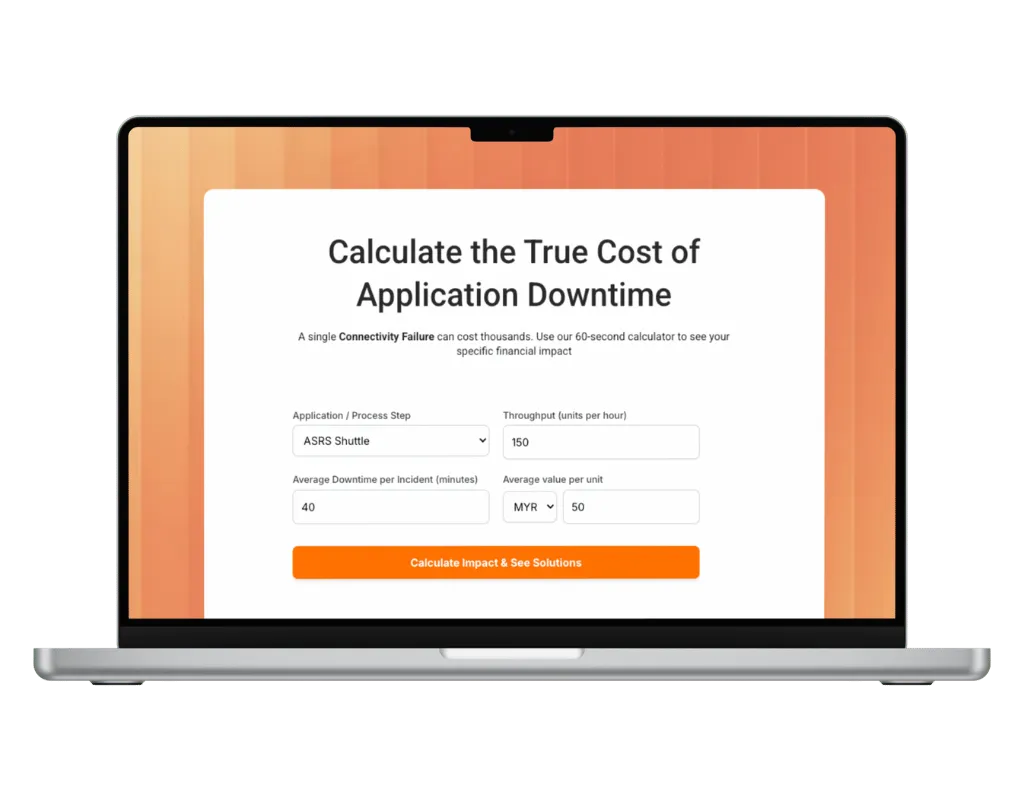

Connectivity Failure Impact Calculator

See the exact financial impact of a line stop. Enter your throughput and downtime minutes to get a hard-dollar cost, making the business case for improvements undeniable.

Translate technical faults into a clear financial impact that gets management's attention.

Get a real-time calculation using just two of your own numbers: average downtime minutes and hourly throughput.

Make data-driven decisions on where to focus your maintenance efforts for the biggest ROI.

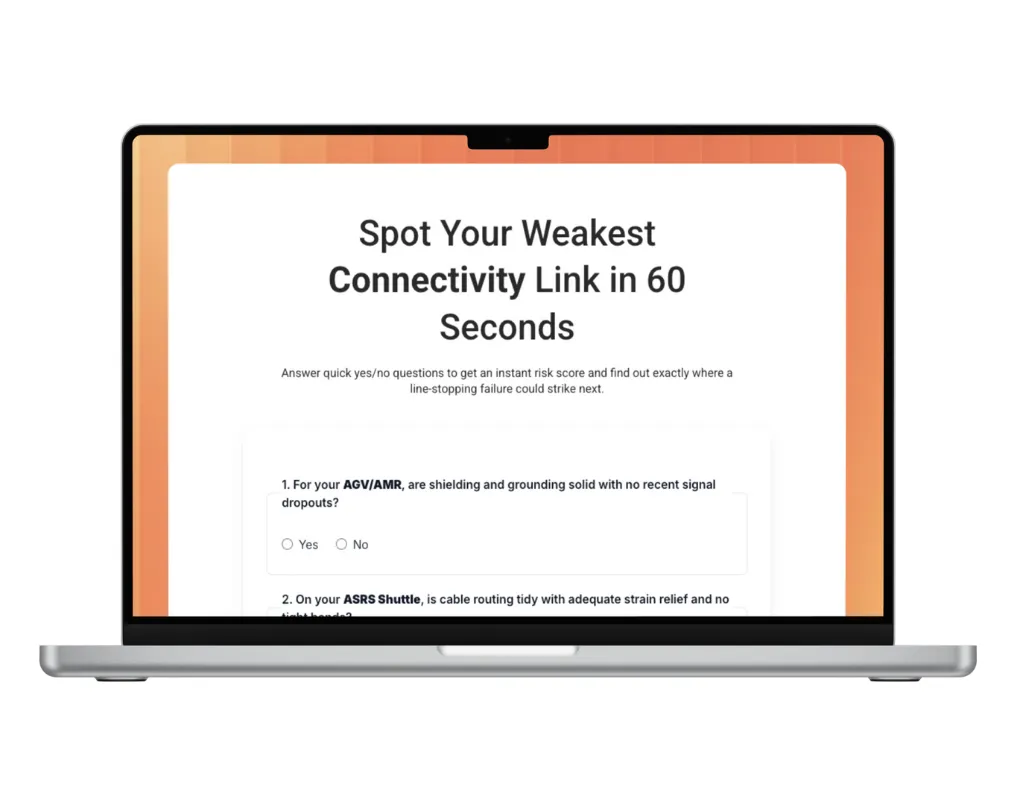

60-Second Connectivity-Failure Self-Audit

Answer 6 quick questions to get an instant risk score. It pinpoints your top vulnerability so you know exactly what to fix first.

Benchmark your system against 8 critical failure points in ~60 seconds.

Get an instant risk score that highlights your #1 vulnerability.

Move from reactive repairs to proactive prevention by spotting hidden risks before they stop your line.

From Audit to Action: A Real-World Scenario

How does the kit work in practice? Imagine an engineer dealing with intermittent faults on a critical crane.

First, he uses the Downtime Calculator to see the financial impact. The “minor” faults add up to more than $12,000/month in lost throughput.

Next, with that cost proof, he runs the 60-second Connectivity-Failure Audit to pinpoint the root cause. The results flag a high risk: the current cables aren’t chain-rated for constant motion.

Finally, he opens the Engineering Spec Pack (Excel), selects the correct ÖLFLEX® crane cable and EMC gland for the application, and prepares the justification.

The result: Immediate budget approval, weak link replaced, and a catastrophic failure avoided—turning a hidden risk into a documented win.

Limited Offer

On-Site Engineering Consultation

For teams that need a deeper analysis, we're offering a complimentary On-Site Engineering Consultation during this pilot phase.

This is more than just a health check. One of our connectivity specialists will partner with your team on-site to:

Provide a second set of expert eyes on your most critical applications.

Share best practices for cable routing and management in high-cycle environments.

Identify subtle risks related to strain, torsion, and EMC interference.

You get a confidential report and actionable advice, at no cost.

Get Your Free Kit Now

Fill out the form below to get instant access to the complete PDF kit.

Frequently Asked Questions

What's inside the Intralogistics Connectivity Survival Kit?

1. 60-second Connectivity-Failure Self-Audit (web/Excel)

2. Downtime Cost Calculator pre-loaded with typical SEA labour & throughput rates

3. Engineering Spec Pack (Excel) with pack-by-pack specs for AGV/AMR, conveyors, small-parts storage, sorter, robotics and ASRS shuttle

Who should use it?

Designed for maintenance engineers, OEM design teams and system-integrator project leads who run automated warehouses in Southeast Asia.

Why focus on cables?

Field data from 37 SEA facilities shows 42 % of unplanned ASRS stops trace back to cable fatigue, abrasion or EMC noise. Cables are <2 % of CAPEX yet trigger most downtime events—so they’re the fastest ROI fix

howe long does the self-audit take?

Few yes/no checks. SWcore pogic follow LEC 60204-1 & DIN EN 50525 <30 = Green. 30-60 = Amber, >60 = Red.

Do I need special software?

No—Excel or Google Sheets is enough. All tools run locally; you don’t send data anywhere.

How fast can I get replacements?

JJ-LAPP stocks key SKUs in regional hubs — we are where you are. JJ-LAPP also has an extensive network of warehouse facilities across Southeast Asia.

Efficiency Boost

Faster, leaner operations.

Cost Savings

Lower operating costs.

Enhanced Accuracy

99 % stock accuracy.

Looking for cables & solutions? Visit the main site → jj-lapp.com

© 2025 JJ-LAPP. All Rights Reserved.