THE MACHINE MAKER CONNECTIVITY SURVIVAL KIT

When machines fail, it’s rarely the PLC – it’s the wiring.

Download the FREE Kit that helps OEMs, panel builders, and integrators detect weak connectivity decisions before they turn into commissioning delays or failure in the field.

Run the 60-Second Connectivity-Failure Audit to uncover risk in your current build

Use the Selection Guide to identify the exact LAPP product family for your application

Download the Engineering Spec Pack with datasheets, approvals, and justification notes

Your Complete Toolkit for Engineering the Right Connectivity Decision

Stop browsing catalogs or guessing part numbers. The Machine Maker Connectivity Survival Kit gives engineers, integrators, and panel builders the three tools they actually need to specify correctly, justify their choice, and prevent build-stage failures.

Stop Searching Catalogs. Start Specifying with Engineering Logic.

Use the Machine Maker Connectivity Selection Guide to identify the correct LAPP product family — based on your real application, motion profile, voltage, screening, torsion, or environmental demands.

Covers Power & Control, Data/BUS, Ethernet, Connectors, Glands, Cabinet Components (ICC), and Tools

Filters by engineering inputs – Application, Voltage, Screening, Core Type, Flexing/Torsion, Certification

Outputs the recommended Product Family with key features, approvals, and technical notes

The 60-Second Connectivity Audit for Machine Builders

Before choosing your cables, connectors, or glands — run this quick audit to check for risk factors like torsion stress, bending radius, shielding, or environment mismatch.

Identify misalignment between your design specs and real motion/environmental demands

Flag torsion, vibration, EMC, and flexing issues early — before BOM submission or commissioning

Get tailored recommendations and proceed directly to the Selection Guide with pre-filled inputs

Engineering Spec Pack

The engineering-ready documentation that helps machine builders, panel designers, integrators, and procurement teams specify the right LAPP product families with confidence — and justify their choice.

Know exactly what to use, why it’s right, and how it performs in real machine environments.

Includes recommended product families, application fit, main challenges, and approval standards

Covers 8 core categories: Power & Control, Data/BUS, Ethernet, Connectors, Glands, Markers, Tools, and Cabinet Components

Downloadable pack with datasheets, IP ratings, approvals, key features, and BOM-ready specifications

From Audit to Selection: A Real Engineering Scenario

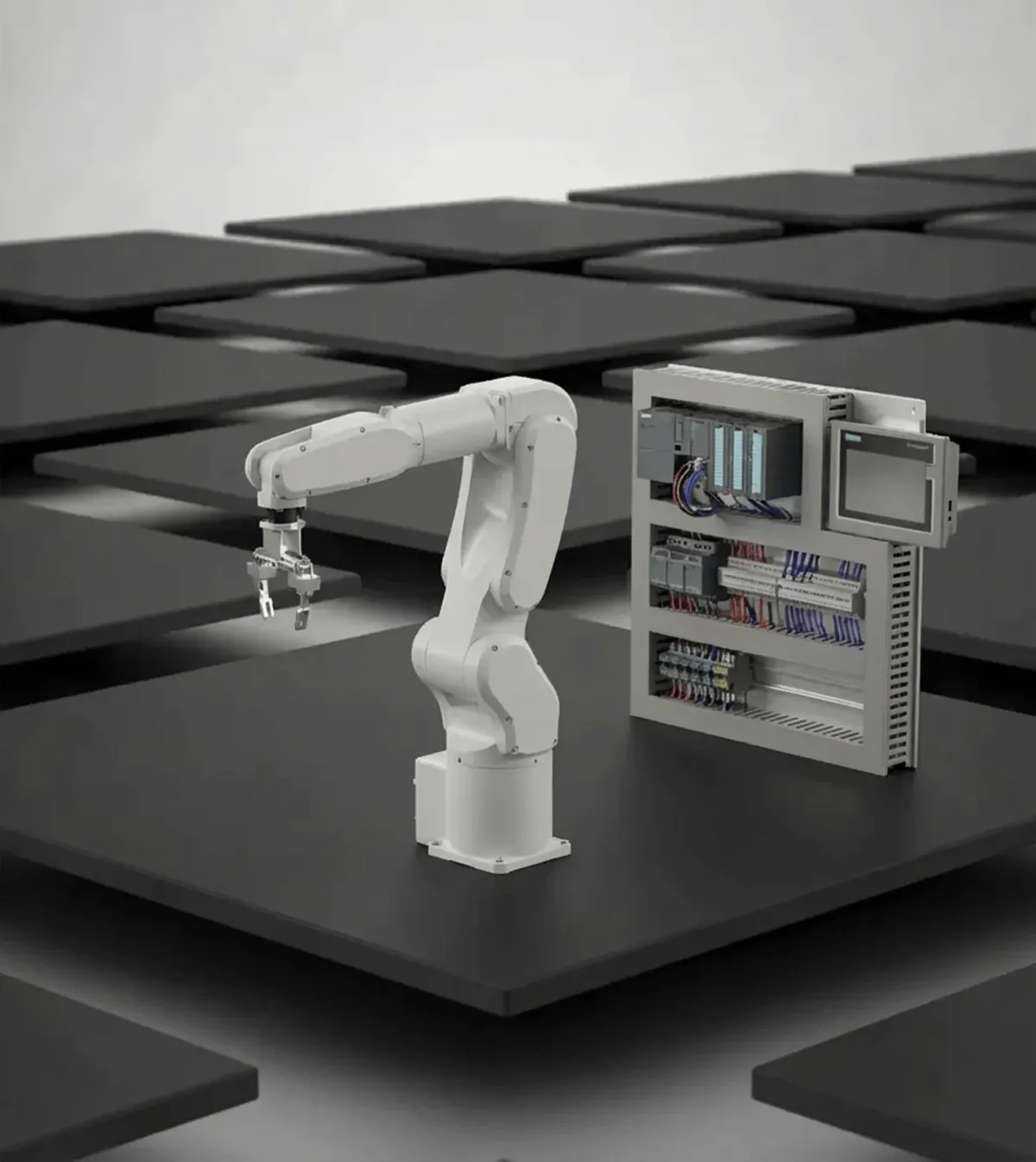

How does the kit work in practice? Imagine a panel builder facing intermittent signal faults in a robotic packaging line.

First, he uses the 60-Second Connectivity Audit to identify risk factors. The audit flags that the current cables are not rated for torsion or EMC protection.

Next, with those findings, he opens the Machine Maker Connectivity Selection Guide to filter by Robotics → Torsion → Screened → Oil Resistant, and receives ÖLFLEX ROBOT 900 P CY as the recommended product family.

Finally, he downloads the Engineering Spec Pack to access datasheets, approvals (UL/CE/VDE), and justification notes to include in the BOM submission.

The result: The procurement team approves the specification instantly, engineering risk is reduced, and the product is correctly documented — before any build-stage issues occur.

Limited Offer

On-Site Engineering Consultation

For machine makers, panel builders, and integrators who need build-stage validation, we’re offering a complimentary On-Site Engineering Consultation during this pilot phase.

This is more than a specification check. One of our connectivity specialists will collaborate with your engineering team to:

Review motion zones, torsion stress, bending radii, and vibration hotspots in robotics, cable tracks, or harnessing

Examine control cabinet wiring layouts — termination quality, space usage, EMC protection, and segregation

Verify approvals (UL, CE, IECEx) and provide BOM-ready product families for specification

You receive a confidential engineering report containing risk findings, recommended product families, and compliant part numbers — at no cost.

Get Your Free Kit Now

Fill out the form below to get instant access to the complete PDF kit.

Frequently Asked Questions

What’s inside the Machine Maker Connectivity Survival Kit?

It includes three engineering tools:

– The 60-Second Connectivity Audit

– The Machine Maker Connectivity Selection Guide

– The Engineering Spec Pack (PDF and web version)

Together, they help you detect risk, select the right LAPP product family, and justify it for BOM approval.

Who should use it?

OEM machine builders, system integrators, panel builders, harnessing subcontractors, and engineering teams responsible for specifying cables, connectors, glands, or control cabinet components.

Why focus on connectivity components?

Most machine failures don’t start in the PLC or motor — they originate from misselected cables, connectors, terminations, or EMC protection. The kit helps prevent these errors before commissioning.

How long does the self-audit take?

It takes less than 60 seconds. You answer a few application-based questions — bending radius, torsion, EMC screening, vibration, heat — and get an instant risk profile.

Do I need special software?

No software required. Everything is web-based, lightweight, and works in any browser. You can also download the Engineering Spec Pack as a PDF.

Does it include part numbers?

Yes. Once you complete the Selection Guide, it recommends the LAPP product family with BOM-ready details, approvals, and datasheet access.

Can I get help from an engineer?

Yes. The kit unlocks access to a complimentary On-Site Engineering Consultation for eligible builds. A connectivity specialist can validate your findings and recommend compliant product families.

Efficiency Boost

Faster, leaner operations.

Cost Savings

Lower operating costs.

Enhanced Accuracy

99 % stock accuracy.

Looking for cables & solutions? Visit the main site → jj-lapp.com

© 2025 JJ-LAPP. All Rights Reserved.